FREQUENTLY ASKED QUESTIONS

What are the advantages of Vapour Blasting?

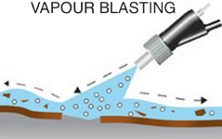

Vapour blasting produces a finer finish than dry blasting and is ideal for the cleaning of more delicate components. Vapour blasting machines use a water and abrasive slurry to simultaneously blast and degrease, preventing impregnation of media onto the component. One of the major advantages of vapour blasting is that it is a dust free process.

Does Vapour Blasting suit all metals?

Typically, all metal components are suitable to be vapour blasted, however depending on the items function, some components may respond better to different surface coatings. We also offer a dry bead blasting surface which restores components in a similar fashion, with slightly different finish.

How can I prepare components for Vapour Blasting?

Components must be entirely dismantled prior to being vapour blasted. This includes removing brackets, bolts and any other items branching off the component, all of which can be treated separately. Some rubber components (seals, cups etc..) respond well to a light vapour blasting treatment, but should still be removed from components.

Commonly Vapour Blasted Parts?

Brite Blast can Vapour Blast all aluminium components and engine blocks, cylinder heads, manifolds, gearbox casings, carburetors, cylinder heads and a whole lot more. Give Brite Blast a call on 076 567 5676 if you have a part that needs to be Vapour Blasted.

How long does Vapour Blasting take?

Depending on the size of the job, our team should be able to have your components back to you within 1 – 3 working days.

How long does Vapour Blasting take?

Depending on the size of the job, our team should be able to have your components back to you within 1 – 3 working days.